PRESS RELEASE

SENER Aeroespacial and CATEC develop a 3D-printed metal antenna for the European Space Agency's PROBA-3 space mission

- It is one of the first space antennas in the world developed using this 3D printing technology, and the first one made in Spain, which is a landmark for the Spanish space industry.

Madrid (Spain), October 8, 2019 -. SENER Aeroespacial and CATEC have completed the delivery of the telemetry and telecommand antennas for the European Space Agency's PROBA-3 mission, for which SENER Aeroespacial is the prime contractor of the entire mission.

This group of antennas includes the first one made by SENER Aeroespacial using metal 3D printing (additive manufacturing). This is one of the first space antennas in the world developed using this technology, and the first one made in Spain, which is a milestone for the Spanish space industry. It also reaffirms the vision of both institutions, SENER Aeroespacial and the research organization CATEC, that it is feasible to use this type of solution as an alternative to conventional manufacturing technology in those cases where the latter does not offer a viable solution.

In recent years, SENER Aeroespacial has been providing and participating in several high- and medium-gain antenna pointing systems for the ESA's main science missions, such as BepiColombo, Solar Orbiter, Euclid and Juice. As part of developing these systems, SENER Aeroespacial designs, verifies and integrates key communications elements, most notably the antennas and the rotating joints integrated inside the mechanisms.

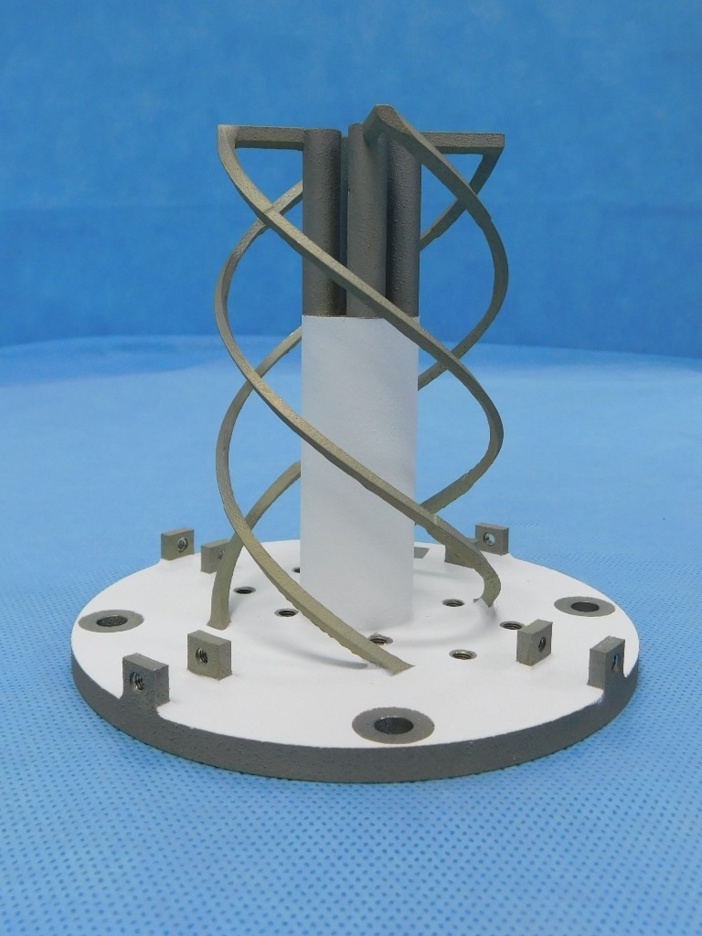

Within this framework, SENER Aeroespacial and CATEC worked to develop a helical antenna that was printed with an aluminum alloy and subjected to demanding verification and qualification tests, which resulted in obtaining the flight acceptance for the European Space Agency's PROBA-3 mission.

"SENER Aeroespacial came to us in 2016 with the challenge of developing a helical antenna for the European Space Agency, and with a real chance of flying. The functional requirements of this product take to the limits additive manufacturing due to the dimensional tolerances for producing such a complex geometry", notes Dr. Fernando Lasagni, Technical Director (Materials & Processes) at CATEC.

“SENER Aeroespacial found the perfect partner and ally in CATEC to achieve the complicated goal of manufacturing and qualifying the first 3D-printed metal antenna, with all the advantages that entails, while maintaining both radio-frequency and thermo-mechanical performance. Both CATEC's previous experience and knowledge and the good communication between the work teams proved fruitful in developing procedures that not only allowed us to deliver the first 3D-printed antenna, but that laid the foundations for future collaborations in which this technology can add value to any SENER Aeroespacial product," says Esteban Celemín, Project Manager for the PROBA-3 antennas at SENER Aeroespacial.

SENER Aeroespacial and CATEC develop a 3D-printed metal antenna for the European Space Agency's PROBA-3 space mission

- It is one of the first space antennas in the world developed using this 3D printing technology, and the first one made in Spain, which is a landmark for the Spanish space industry.

Madrid (Spain), October 8, 2019 -. SENER Aeroespacial and CATEC have completed the delivery of the telemetry and telecommand antennas for the European Space Agency's PROBA-3 mission, for which SENER Aeroespacial is the prime contractor of the entire mission.

This group of antennas includes the first one made by SENER Aeroespacial using metal 3D printing (additive manufacturing). This is one of the first space antennas in the world developed using this technology, and the first one made in Spain, which is a milestone for the Spanish space industry. It also reaffirms the vision of both institutions, SENER Aeroespacial and the research organization CATEC, that it is feasible to use this type of solution as an alternative to conventional manufacturing technology in those cases where the latter does not offer a viable solution.

In recent years, SENER Aeroespacial has been providing and participating in several high- and medium-gain antenna pointing systems for the ESA's main science missions, such as BepiColombo, Solar Orbiter, Euclid and Juice. As part of developing these systems, SENER Aeroespacial designs, verifies and integrates key communications elements, most notably the antennas and the rotating joints integrated inside the mechanisms.

Within this framework, SENER Aeroespacial and CATEC worked to develop a helical antenna that was printed with an aluminum alloy and subjected to demanding verification and qualification tests, which resulted in obtaining the flight acceptance for the European Space Agency's PROBA-3 mission.

"SENER Aeroespacial came to us in 2016 with the challenge of developing a helical antenna for the European Space Agency, and with a real chance of flying. The functional requirements of this product take to the limits additive manufacturing due to the dimensional tolerances for producing such a complex geometry", notes Dr. Fernando Lasagni, Technical Director (Materials & Processes) at CATEC.

“SENER Aeroespacial found the perfect partner and ally in CATEC to achieve the complicated goal of manufacturing and qualifying the first 3D-printed metal antenna, with all the advantages that entails, while maintaining both radio-frequency and thermo-mechanical performance. Both CATEC's previous experience and knowledge and the good communication between the work teams proved fruitful in developing procedures that not only allowed us to deliver the first 3D-printed antenna, but that laid the foundations for future collaborations in which this technology can add value to any SENER Aeroespacial product," says Esteban Celemín, Project Manager for the PROBA-3 antennas at SENER Aeroespacial.

CATEC, along with Airbus, has already developed the titanium supports for the solar panels of a telecommunications satellite (a milestone in Europe due to the criticality of the components) and more than hundred fittings, brackets, fairings and other applications for the aeronautical and space industry. Together with the company CITD, CATEC has also developed titanium and aluminum hoisting tooling for the CHEOPS satellite, and they are currently working on developing the secondary structure for the JUICE mission, as well as other hardware for the Ariane launcher. "The experience we have gained in other programs where we have developed flight components made of titanium alloys was essential for SENER Aeroespacial and the European Space Agency to trust in this team of engineers & researchers for this ambitious project", states Lasagni.

"The work of CATEC consisted in supporting SENER Aeroespacial in the design of the antenna, integrating into it the manufacturing possibilities and constrains for the technology, defining the validation tests and developing the quality assurance process for manufacturing flight components, and at the same time complying with ESA's rigorous verification process”, notes Carlos Galleguillos, Project Manager at CATEC.

Moreover, "SENER Aeroespacial was responsible for the design, machining of the interfaces and conducting an intensive functional, thermal, radiofrequency and vibration testing program. All of the tests were completed successfully, which resulted in obtaining the flight permit for the antenna”, explains Eduardo Lapeña, the thermo-mechanical engineer at SENER Aeroespacial who is responsible for these antennas on the PROBA-3.

About PROBA-3

In addition to being a global first from a technological standpoint, the PROBA-3 mission will open up space for smaller (ESA) member states and small and medium-sized companies. PROBA-3 is the first precision formation flight mission for ESA and the world. A pair of satellites will fly together in a fixed configuration, acting as one "large, rigid structure" in space, to test the technologies for flying in formation.

SENER is the main contractor for the PROBA-3 and leads a consortium of European companies from more than 10 countries. The mission will demonstrate flying in formation in the context of a large-scale scientific experiment. The paired satellites will together form a 150-m long solar coronagraph to study in more detail than ever the weak outer corona of the Sun. In addition to its scientific interest, the experiment will provide the perfect instrument for measuring how precisely the two spacecraft can be positioned. The launch of PROBA-3 is scheduled for late 2020.

About SENER Aeroespacial

SENER Aeroespacial has been a leading supplier of high performance aerospace systems for Space, Defence and Science for more than 50 years, with high added value technological developments. In Space, it supplies electromechanical components and systems, navigation systems (GNC/AOCS), communications, astronomy and optics systems for Space, and it is currently participating in the main programs of ESA and NASA (including Euclid, Meteosat Third Generation, Solar Orbiter, JUICE, Proba-3, Hubble, Galileo, Rosetta, Gaia, Herschel and Planck, IXV, BepiColombo and Mars 2020) and the European Space Observatory; in the Space commercial market, is a leading supplier of telemetry and telecommand antennas and a regular supplier of all types of antennas, passive equipment and radio frequency assets for the leading international manufacturers of communications satellites, even in programs for the so called New Space. In Defence, it develops electromechanical systems, COMINT (communications intelligence) and communications links (D-Link), as well as helicopter modernization services. In Astronomy and Science, it produces precision mechanical equipment for terrestrial telescopes and engineering services. And, finally, its ATC & Broadcast division is a supplier of antennas and passive units.

SENER Aeroespacial is part of the SENER engineering and technology group, founded in 1956. The SENER Group has 2,300 professionals in offices in four continents and the group's operating revenue exceeded 589 million Euros (2018 data).

About FADA-CATEC

CATEC is an advanced technology center that helps improve the competitiveness of aerospace companies through technological research and innovation, knowledge creation, technology transfer and advanced services. It is supported by the Andalusian Foundation for Aerospace Development (FADA), an entity that is chaired by the Council for Employment, Business and Commerce through the IDEA Agency, and has a staff of over 60 specialists and technicians. Over its ten-year history, it has become one of the most active technology centers in national and European R&D projects, with a special emphasis on developing advanced technologies and applications for advance manufacturing, Industry 4,0, unmanned aerial systems or drones (UAS/RPAS), aerial robotics, robotics and automation and non-destructive testing. It is currently working on more than 60 R&D projects, both with public research organizations and private companies. In several of them, it is spearheading initiatives under the European Commission's 7th Framework, Clean Sky and Horizon 2020 programs.

CATEC's Communication manager

Celia Ruiz

cruiz@euromediagrupo.es